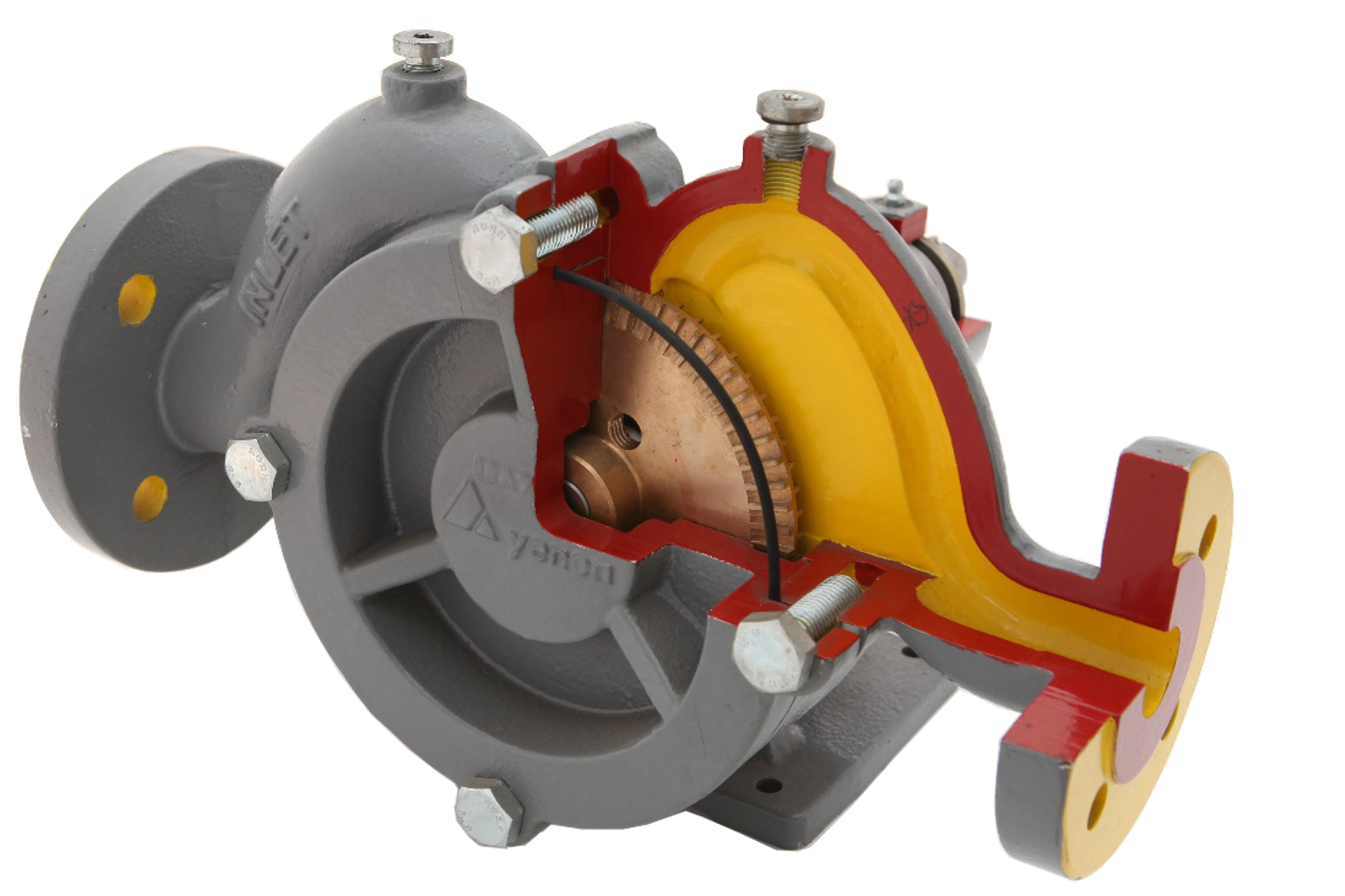

Yenen LPG Pump is a special pump that enters the turbine pump zero. The liquid fills the turbine around the pump from the inlet of the pump and the turbine gives motion to the fluid between the power it receives from the engine and the fins. When the liquid completes one cycle in the pump, it turns towards the outlet of the pump. When we increase the power of the electric motor, pumping power and differential pressure increase. But at this time, the capacity of the pump is reduced. Differential pressure is the difference between the pressure at the inlet of the pump and the pressure at the outlet.

The turbine is the only moving part of the pump and has no connection with the body. If liquids such as LPG or ammonia are used in the eaten LPG pump, there is no practical wear on the turbine due to the lubrication feature of these products.

Pumping liquid volume is one of the most difficult pump applications. Unlike other pump applications, its design, manufacture, installation and operation require more attention.

Yenen Lpg Pump is especially suitable for liquid products. It is very easy to maintain and operate. Spherical graphite casting is used in the production of pressurized parts.

The turbine is mounted firmly on the shaft. Thus, we can easily change the turbine piping system and electric motor without any tools.

We can easily replace the packing and O-Rings turbine piping system and electric motor without the need for any tools.

Advantages

- Easy to Use and Maintain

- Long life

- ATEX Approved

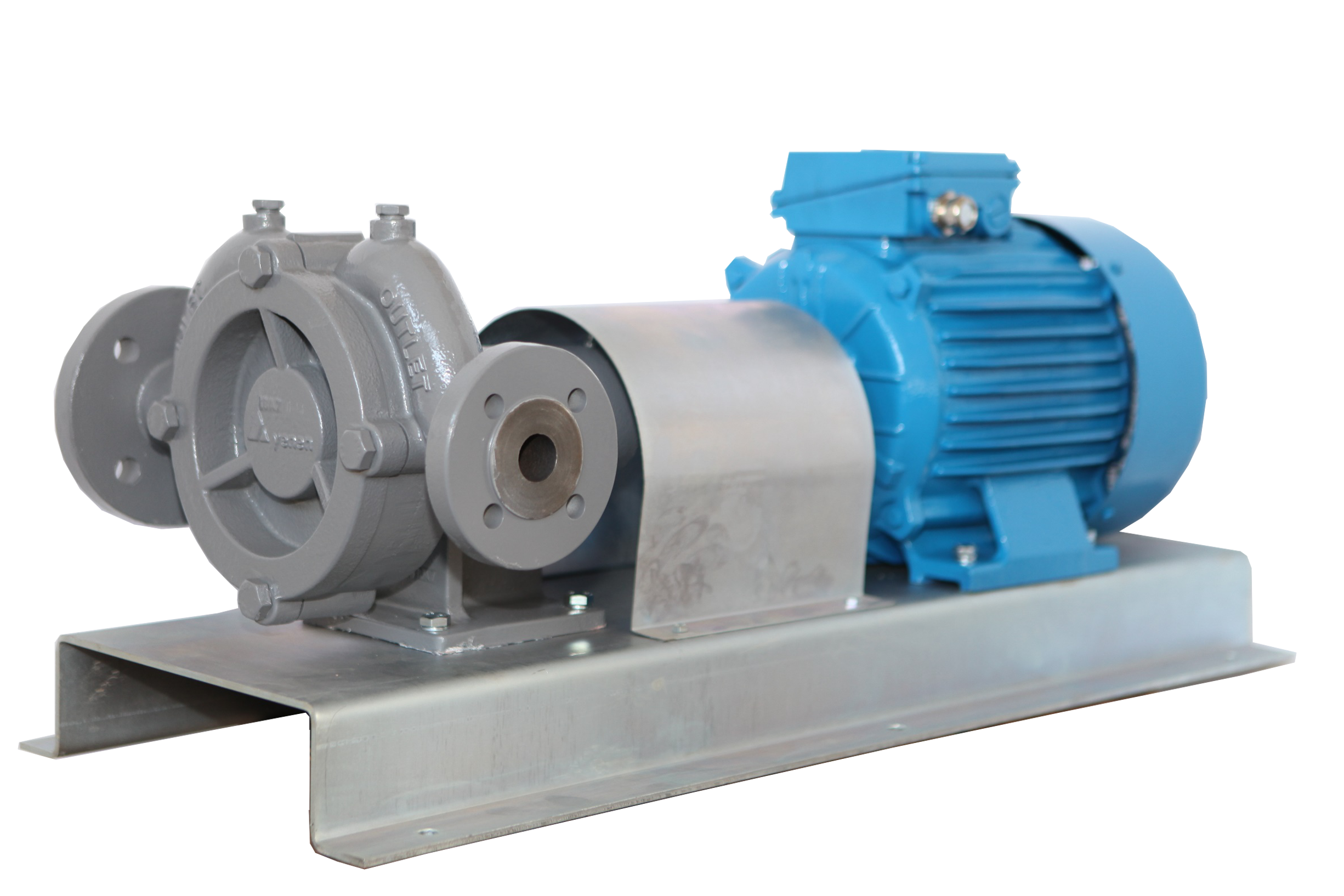

Mechanical Specifications

- Inlet Connection: DIN2635 (Optional: 1 ½’’ ANSI Flange)

- Outlet Connection: DIN2635 (Optional: 1’’ ANSI Flange)

- Flowrate: 125 lt / min @ 7.5 bar

- Max Working Pressure 27.6 bar

- Max Differential Pressure: 17.2 bar

- Ambient Temperature: -30°C / +90°C

- Max Motor Capasity: 15 kW (20 HP)

- 5.5 kW, rpm: 2880 @ 50 Hz or 3450 @ 60 Hz